Five Easy Ways to Keep Your CIPP System Healthy

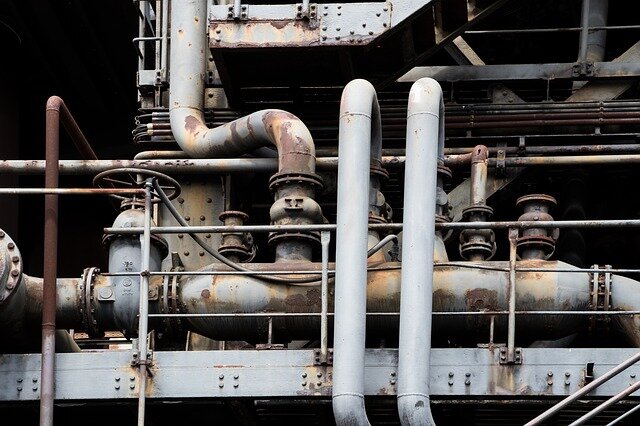

A CIPP system is one that survives on cured-in-place pipe repair and maintenance. Commercial property owners have benefited greatly from these procedures. Next to traditional methods, these are eco-friendlier and more reliable. If you manage a property, you want to keep sewer, chemical, or any other kind of pipe systems healthy.

To do so, certain steps need to be taken – some just on occasion, some a little more often. With cured-in-place pipe repair, these steps are not overly complicated. In fact, maintaining a commercial pipe system comes down to this: CIPP liners, easy entry points, replacing old pipe sections, precision work, and scheduling regular inspections.

CIPP Liners

At the heart of cured-in-place methods, CIPP is essential to solidifying pipes. These slip-liners are designed to work with existing pipe parameters, which can determine the thickness of the liner, as well as how long it will hold up. Factors like pipe diameter, current conditions, and depth or shape might be incompatible with outdated methods. However, with CIPP, contractors can apply liners to any commercial system.

This includes any configuration with multiple transitions and bends. Industrial slip lining works to strengthen the entire piping system. A CIPP system lasts because the resin bonding procedure is made to withstand environmental wear and tear. Our contractors can do a slip-line installation on the spot, no matter what your business entails. CIPP works for government buildings, schools, offices, and more.

Easy Entry Points

The key to good pipe repair is establishing an entry point – ideally, one that is not destructive to the landscape or established piping. Without cured-in-place pipe repair, contractors might need to make an entry point that’s impossible to completely cover up. Once the process is finished, you want pipe repairs to be unnoticeable.

With CIPP, the contractor can expertly cure resin through a simple – and often tiny – entry point. In the end, your property will have tight-fitting, joint-less, and corrosion-resistant pipes. CIPP is designed for commercial pipes, so contractors come prepared with tools to inject resin in innovative ways, all without damaging the structure or grounds.

Replacing Older Pipe Sections

There comes a time when a pipe section fails, whether due to old age or by outside forces. Clearly, replacing those older sections is the only way to keep things working normally. What isn’t obvious is the way to do this without racking up costs.

For a CIPP system, a tool is inserted at the entry point of the existing tube. The tool is connected to a new pipe, all ready to slide into place once the old pipe is burst. This process allows damaged sections to be destroyed while drawing its replacement in. CIPP allows every piece of the old pipe to be removed quickly and safely by your contractor.

Precise and Fast Work

With CIPP, contractors can work quickly and precisely. Unlike traditional methods, most jobs are completed within 24 hours, barring any unforeseen issues. We can open and reinstate any water service connections sooner rather than later, keeping your commercial properties unburdened.

Scheduling Regular Inspections

Keeping a healthy pipe system is easy if you schedule regular inspections. Should there be a problem in the making, our contractors can find and stop it before it gets worse. We use a flexible camera, one that allows an inspection of the damaged pipe if it’s difficult to reach. Using this threaded-in camera, we can determine where repairs need to be made and how.

A Healthy CIPP System

We offer CIPP repairs and maintenance to keep your water systems going. Our contractors are equipped to avoid expensive, time-consuming work. Every step counts. Call now if you desire a healthy CIPP system.